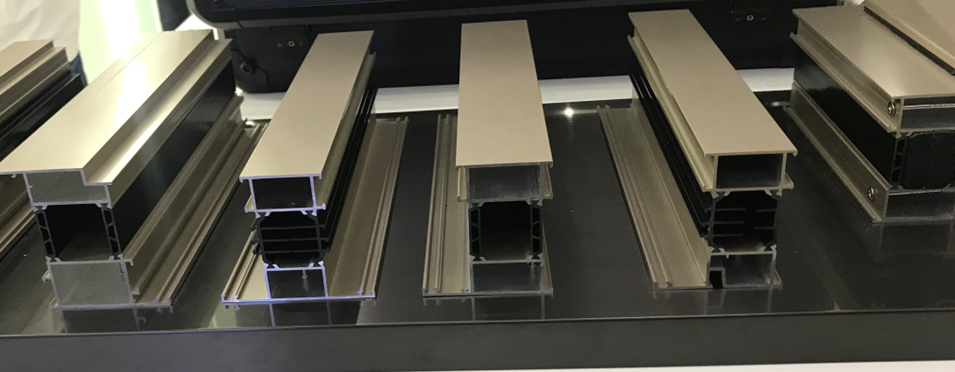

Xingda:your preferred door and window aluminum profile manufacturer

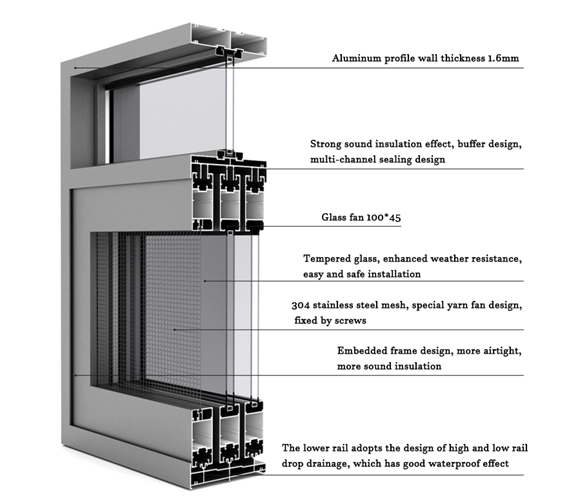

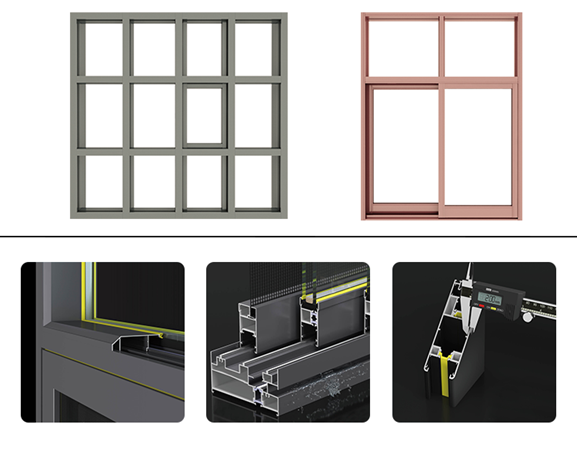

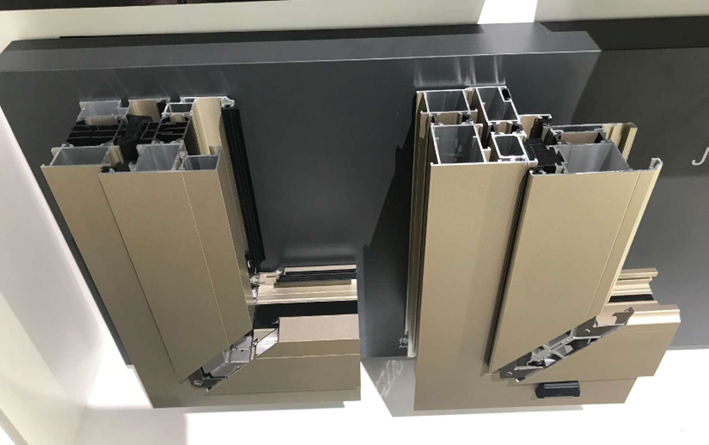

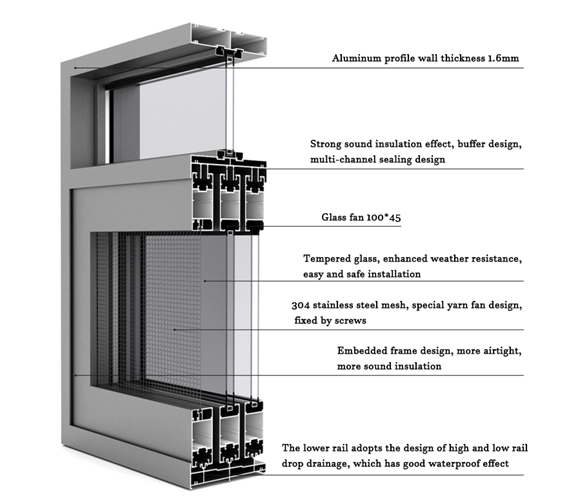

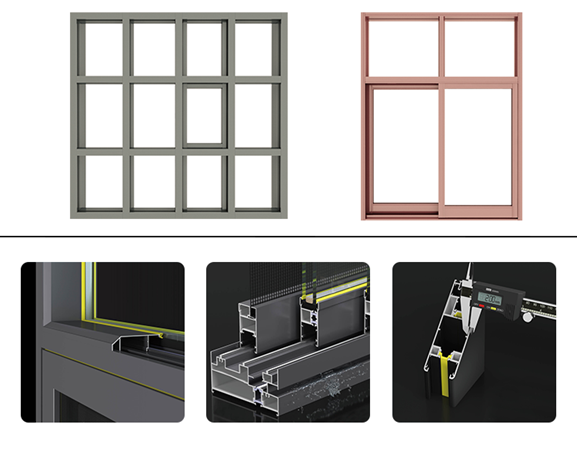

Xingda aluminum profiles for doors and windows can withstand high loads and can be processed according to your actual needs. It is not easy to deform in high temperature environments and has received positive feedback from customers.

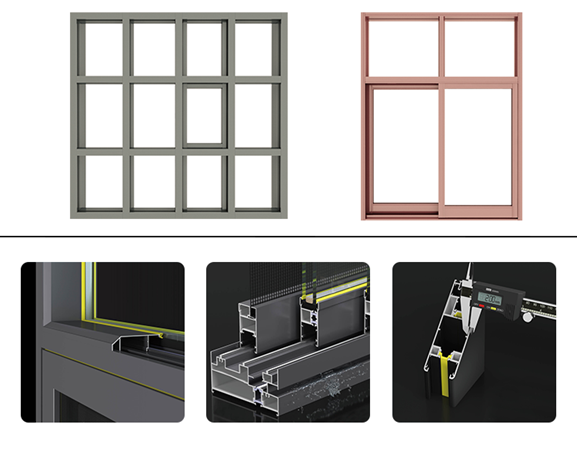

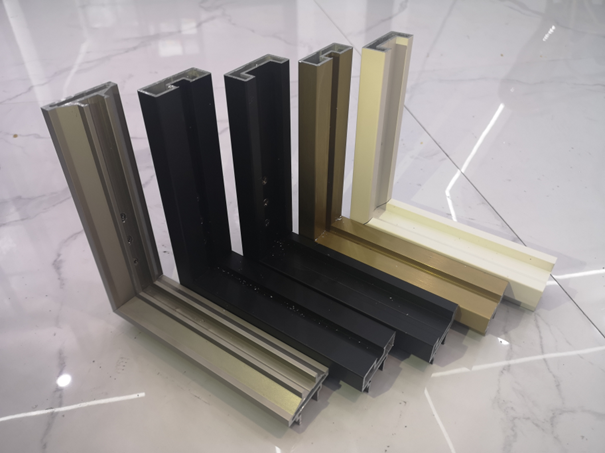

As a popular choice for doors and windows of modern buildings, aluminum profiles for doors and windows bring you a fresh and simple visual effect.At the same time, it also provides you with a good experience.

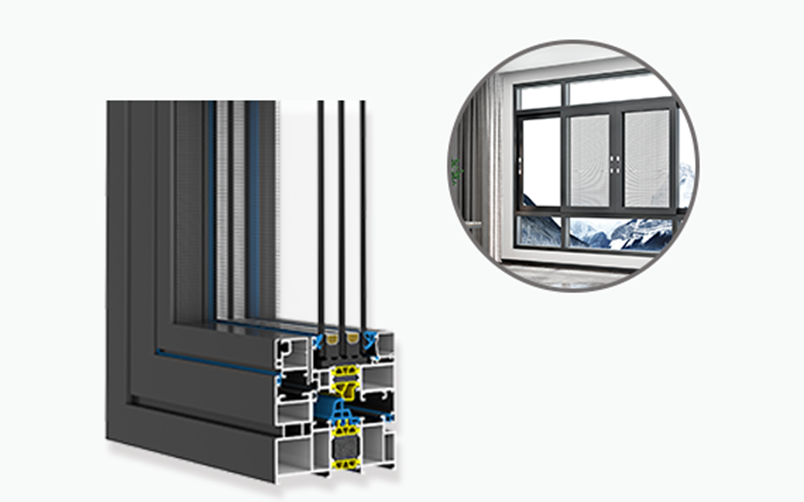

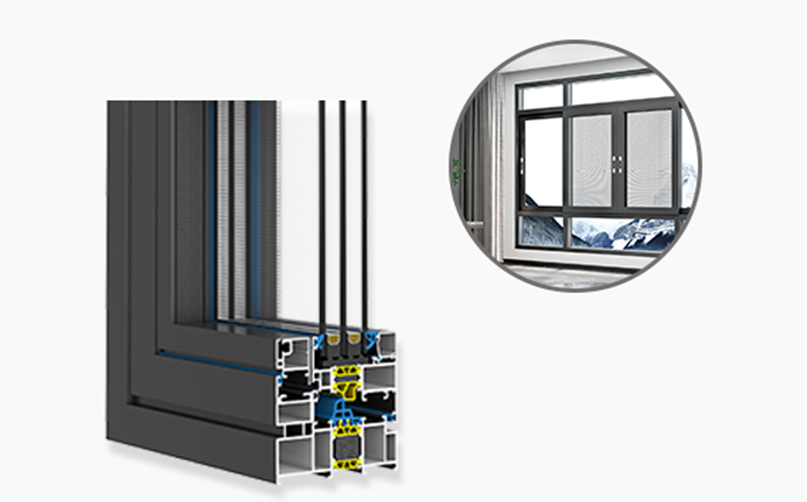

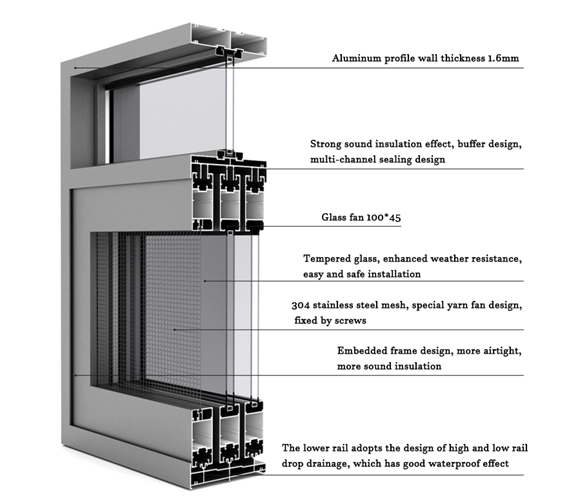

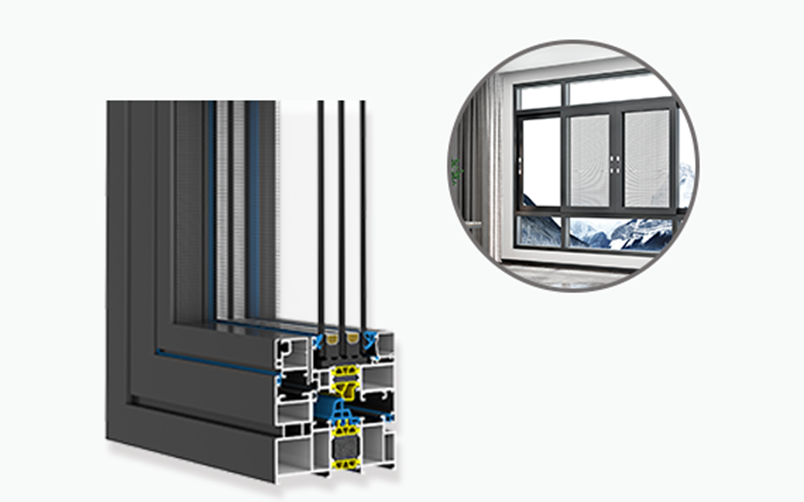

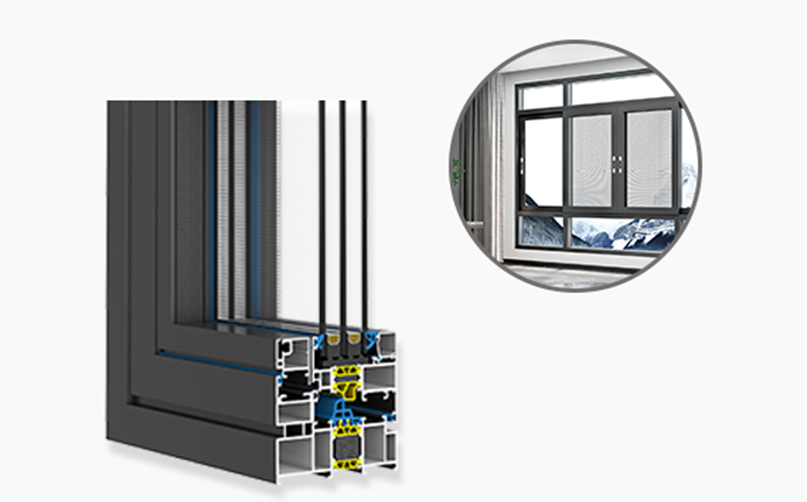

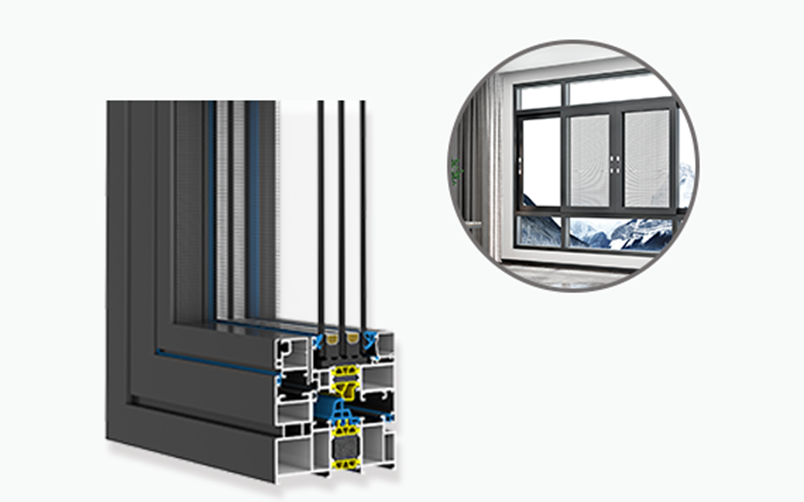

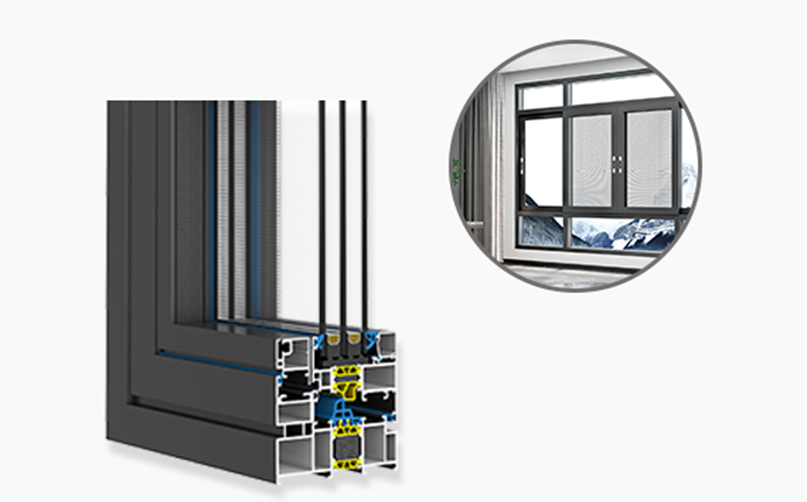

Xingda uses imported nylon heat insulation strips, which have excellent anti-aging and anti-ultraviolet properties, and the thermal expansion coefficient is close to that of aluminum profiles.Ensure that the heat insulation strip is closely combined with the aluminum profile under the condition of large temperature difference

Aluminum profiles for doors and windows are also suitable for large-scale

glass curtain walls and bay window designs, creating a modern architectural

appearance

As a professional aluminum profile manufacturer, Xingda can provide you with

one-stop service from aluminum extrusion production to aluminum deep processing

As a professional aluminum profile manufacturer and exporter with 30 years of manufacturing and sales experience, Xingda Aluminum specializes in manufacturing high-quality door and window extrusion profiles, which are suitable for various architectural doors and windows, such as family houses, villas, office buildings, Commercial buildings, hotels, hospitals, schools and public buildings, etc.

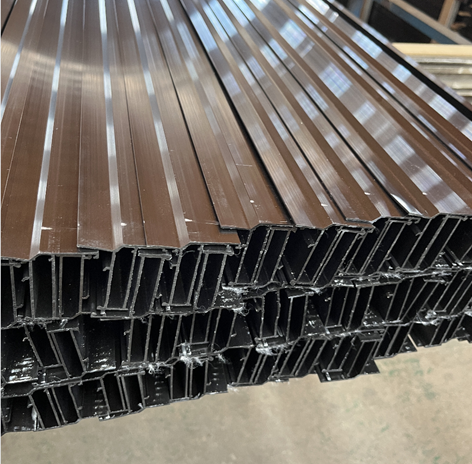

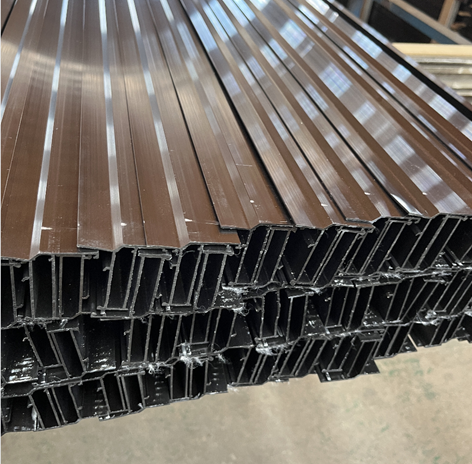

Xingda has a wide range of products from aluminum ingot casting, mold making, extrusion, anodizing, coloring, electrophoretic coating, electrostatic powder coating,

Wood grain production line, strip heat insulation and other complete production lines

Xingda provides door and window aluminum processing services such as bending, uncoiling, welding, punching, and cutting

Xingda positions itself as a global aluminum profile solution provider based in China, which can meet your different types of needs,

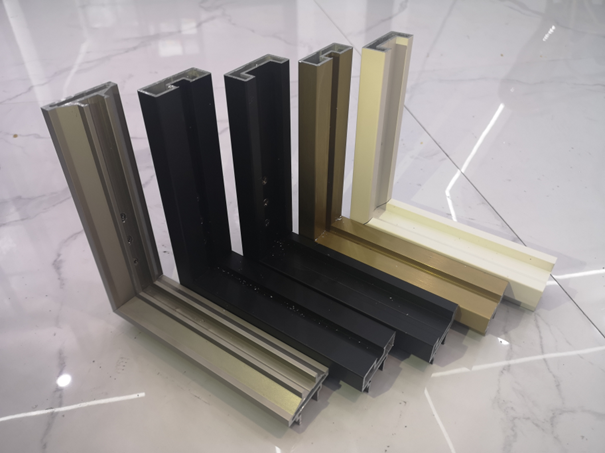

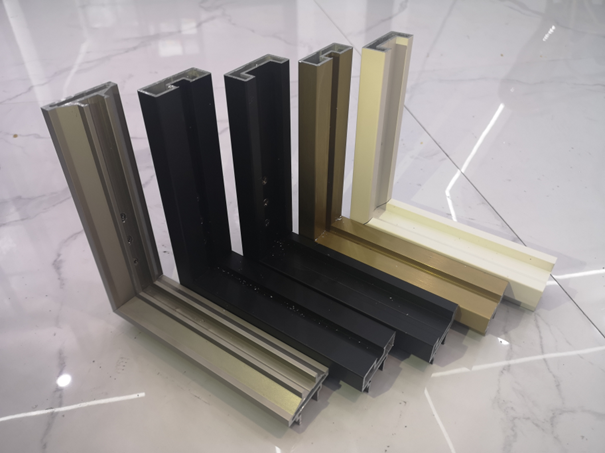

Choose from a wide range of finishes and colours, contact us today for an aluminum catalog and quote

Xingda can give you 100% quality control and competitive price

Aluminum Profiles for Doors and Windows :FAQ and Answers

Aluminum profiles for doors and windows can be made into sections of various

shapes and sizes through extrusion, cutting, welding and other processing

techniques to meet the needs of different architectural styles and interior

decoration. From simple modern to retro classic, from straight line to curve,

aluminum profiles can be flexibly applied to various design concepts to achieve

unique spatial effects. It can meet the needs of different scenarios and create

more creative and functional spaces for architects and designers.

Process flow of aluminum profiles for doors and windows?

Common problems and preventive measures of aluminum profiles for doors and windows?

How much is a ton of aluminum profiles for doors and windows?

What is the wall thickness standard of aluminum profiles for doors and windows?

How to calculate the content of aluminum alloy doors and windows aluminum profiles?

What are the hardware accessories for aluminum profiles of doors and windows?

Precautions for choosing aluminum profiles for doors and windows?

Specifications and dimensions of aluminum profiles for doors and windows?

Aluminum alloy doors and windows aluminum profile content reference table?

Loss of door and window profiles?

What is the difference between 70 series and 80 series of aluminum alloy door and window profiles?

What is the service life of aluminum profiles for doors and windows?

How to see the profile diagram of broken bridge aluminum doors and windows?

Aluminum door and window profile hardness?

Classification of aluminum window frame profiles?

Classification of aluminum door frame profiles?

What are the door and window profile series?

What are the types of energy-saving aluminum door and window profiles?

What are the series of broken bridge heat insulation aluminum alloy profiles?

What is a thermal break bridge aluminum profile?

What are the production processes of aluminum profiles for doors and windows?

The production process of aluminum alloy door and window profiles includes three major processes: smelting, extrusion molding, and coloring, and the coloring process includes three options: anodic oxidation, air oxidation, and fluorocarbon painting.

Raw materials: according to the actual aluminum alloy profiles that need to be produced, calculate the amount of various aluminum alloy components added, and effectively match various raw materials;

Smelting: The selected raw materials are added to the melting furnace for melting according to the processing technology regulations, and the slag and gas in the melt are reasonably removed according to the degassing and slagging refining methods;

Forging: Under certain forging process standards, the smelted aluminum liquid can be turned into round casting rods of various specifications and models after water cooling according to the deep water well forging system software.

2. Extrusion process of aluminum alloy door and window profiles

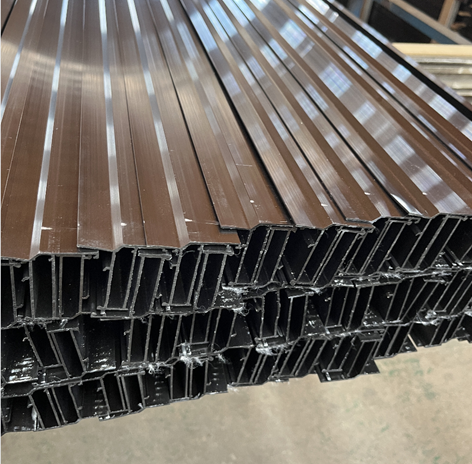

Extrusion molding is carried out on an automatic production line consisting of ingot heating, extrusion, cooling, tension straightening, sawing and other processes.

The equipment on the production line includes induction heating furnace, extrusion machine, furnace table, discharge conveyor, profile lifting and transferring device, cooling bed, tension leveler, storage table, tractor, sawing machine, etc.

Induction heating furnace, the heating temperature of the ingot is generally controlled at 400 ° C ~ 520 ° C, if the temperature is too high or too low, it will directly affect the extrusion molding. The extrusion machine generally adopts a single-action hydraulic press, and its tonnage is between 1200 tons and 2500 tons.

The diameter of the extrusion cylinder of the extrusion machine varies with the tonnage of the extrusion machine. The larger the tonnage of the extrusion machine, the larger the diameter of the extrusion cylinder.

The diameter of the extrusion cylinder is generally in the range of 150mm~300mm. The working temperature of the extrusion tool is 360°C~460°C, and the extrusion speed is 20 m/min~80m/min. Extrusion tools mainly include dies. Extrusion dies are divided into flat dies, split dies, tongue dies and splitter combined dies according to their structural characteristics. The production of aluminum alloy door and window profiles mostly uses flat dies and split split dies.

The discharge table receives the profile extruded from the extruder and transfers the profile to the discharge table. Most of the discharge workbench is a horizontal strip transport model, and the movement speed of the horizontal strip is synchronized with the extrusion speed.

The cooling bed is mostly of walking beam type, and a considerable number of fans are installed below to ensure uniform cooling of the profiles, so that the temperature of the profiles is lower than 70°C before straightening.

The tension straightening machine is equipped with torsion jaws, which can stretch and straighten while torsion correction. After the tension leveler is the material storage table, which provides profiles to the sawing machine table, and the sawing machine cuts the profiles according to the fixed length.

3. Coloring treatment of aluminum alloy door and window profiles

The surface treatment of aluminum alloy door and window profiles is mostly anodized to make the surface of the profiles silvery white. Surface treatment can enhance the profile appearance and prolong the service life of aluminum door and window profiles.

Anodizing process flow: loading→degreasing→water washing→alkali etching→warm water washing→cold water washing→neutralizing light→water washing→anodizing→cold water washing→warm water washing→sealing→drying→unloading→finished product inspection→packaging The thickness of the oxide film after anodic oxidation of aluminum door and window profiles is not less than 10 μm.

The surface treatment of aluminum door and window profiles can also be colored. Aluminum profiles that require other colors can be obtained by natural oxidation coloring, electrolytic coloring and dipping coloring.

How to connect aluminum profiles for doors and windows?

Mechanical connection

Mechanical connection is a common connection method, which connects two or more materials together through fasteners such as screws and expansion bolts. It is a simple and reliable connection method. When connecting aluminum profiles for doors and windows, we can use corner codes, plate connectors and other materials, and connect them to the aluminum profiles with fasteners such as screws or expansion bolts.

Fusion connection

Welding connection is a high-strength connection method, which forms a whole by welding two or more materials together to achieve a tight and seamless connection effect. When connecting aluminum profiles for doors and windows, we can use arc welding, argon arc welding, etc. for welding to achieve a firm connection.

Adhesive connection

Adhesive bonding is a method of joining materials together using glue or adhesives. Unlike mechanical bonding and fusion bonding, the bonding effect depends on the performance and maintenance of the adhesive. When connecting the aluminum profiles of doors and windows, we can use special glue or adhesives to connect the aluminum profiles of doors and windows together.

No matter which connection method is used, we should pay attention to the following points when connecting aluminum profiles for doors and windows:

• Suitable materials and fasteners must be used to enable the connection to withstand the loads under normal service conditions.

• Before connecting, the surface of aluminum profiles for doors and windows must be carefully cleaned to ensure that the surface is clean and free of oil.

• When connecting, you must strictly follow the connection method to ensure that the connection is firm and reliable.

Generally speaking, there are various connection methods for aluminum profiles of doors and windows, and we can choose different connection methods according to specific conditions to achieve a good connection effect. At the same time, when connecting aluminum profiles for doors and windows, the connection method must be strictly followed to ensure that the connection is firm and reliable.

Why is aluminum most suitable for door and window profiles?

Aluminum is a metal with light weight, good toughness and corrosion resistance, so it is widely used in the manufacture of door and window profiles. Here are a few important reasons why aluminum profiles are best suited for windows and doors:

Lightweight and corrosion-resistant: Aluminum material has low density and light weight, which makes the installation of aluminum doors and windows more convenient. Aluminum has excellent anti-oxidation and corrosion resistance. Even if it is used for a long time in a humid environment, it will not rust and can maintain a long-term aesthetics.

High strength and good rigidity: aluminum profile products have high strength, good rigidity, strong resistance to external impact, and are not easy to deform. In the manufacture of doors and windows, it is necessary to maintain a certain degree of rigidity, which is very important to ensure the service life and stability.

Good processability and diverse designs: aluminum profiles are easy to process, and can be flexibly processed and designed according to different door and window design requirements. In addition, the surface treatment of aluminum profiles can also achieve different colors and textures, so it has a wider degree of freedom in aesthetics and design.

Environmental protection and energy saving: aluminum products can be recycled and reused, which meets a large number of environmental protection requirements. Moreover, doors and windows made of aluminum profiles have good sound insulation and thermal insulation properties, which can effectively reduce energy consumption and environmental protection emissions.

Therefore, aluminum profiles are currently one of the best materials in the manufacture of doors and windows. Aluminum products not only ensure the safety, stability and durability of doors and windows, but also meet different design requirements. At the same time, they also have the advantages of environmental protection and energy saving, so they have irreplaceable advantages in the door and window industry.

What are the mechanical properties of aluminum profile doors and windows?

High strength. Aluminum is a metal material with high strength, and its hardness and compression resistance are relatively strong. During the manufacturing process of doors and windows, the fastness and bearing capacity of aluminum ensure the overall stability and safety of doors and windows.

Strong corrosion resistance. Aluminum has excellent corrosion resistance and can be used for a long time in various harsh environments without damage. This means that aluminum profile doors and windows will not corrode, rust, or deform, ensuring the long-term use of doors and windows.

Good thermal conductivity. Aluminum has good thermal conductivity, which can quickly transfer heat, reduce local heat accumulation in doors and windows, ensure indoor ventilation and uniform temperature distribution, and improve the comfort of doors and windows.

Lightweight. Aluminum is a lighter metal material that is easy to handle and install. Lightweight doors and windows play a very positive role in reducing the load of the overall building structure.

What is the price of aluminum profiles for doors and windows?

The price of aluminum profiles for doors and windows varies greatly. The main factors are as follows:

Aluminum profile cost: The raw material of aluminum profiles for doors and windows is aluminum ingots. If the price of aluminum ingots decreases, the price of aluminum profiles for doors and windows will also decrease.

Shape and size: The more complex the shape and size of aluminum profiles for doors and windows, the higher the price.

To meet higher requirements for door and window design. Therefore, the price of aluminum profiles for doors and windows will be affected by the shape and size.

Processing methods: There are many processing methods for aluminum profiles, such as anodizing, powder coating, coating process, etc. for surface treatment. Different processing methods have different degrees of complexity, which means that prices are also different.

Purchase quantity: If you need more aluminum profiles, the price will be cheaper, because the batch price is different.

Wall thickness: The wall thickness is different, which means that the meter weight is different, so the price is also different.

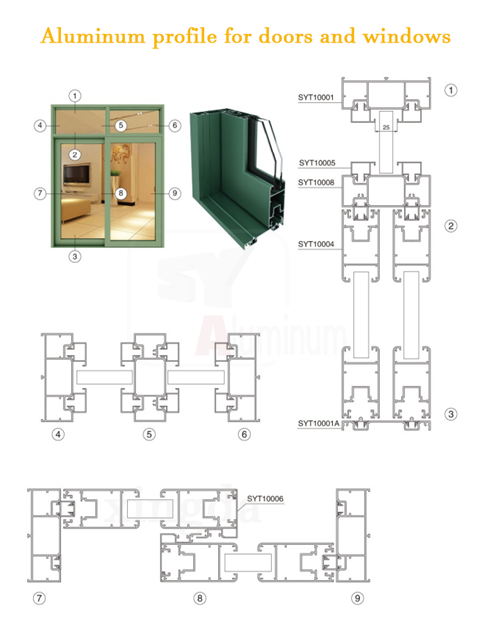

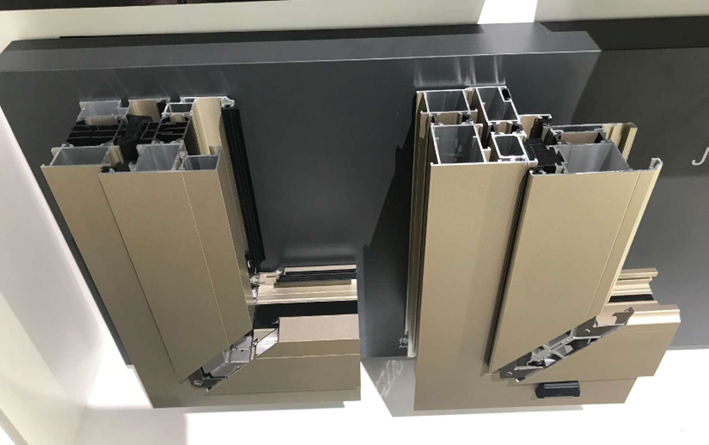

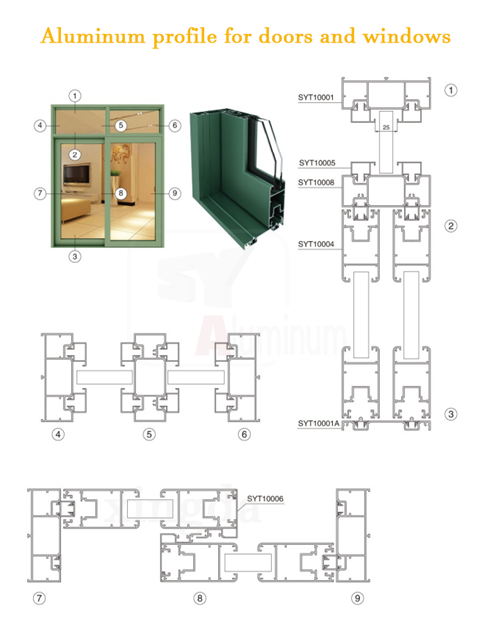

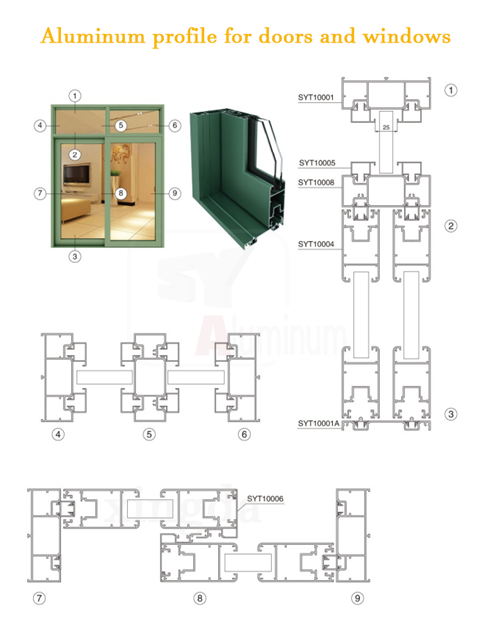

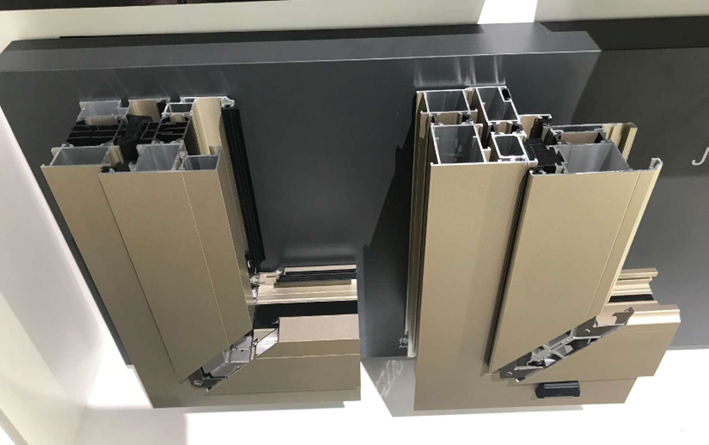

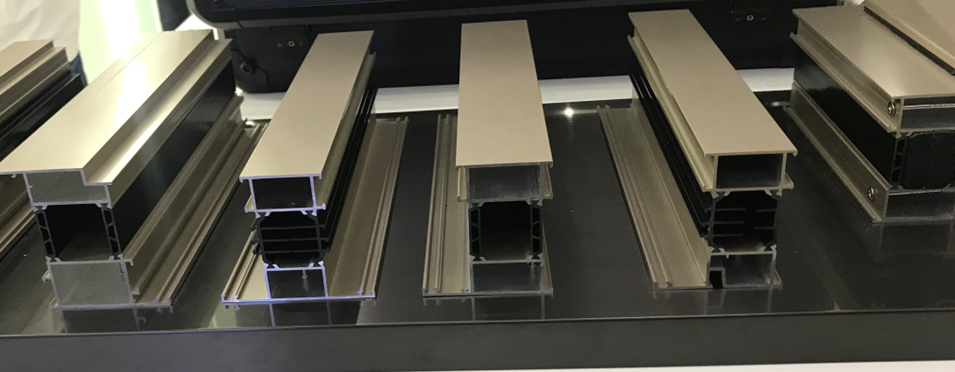

What are the specifications of doors and windows?

The specifications and dimensions of aluminum door and window profiles are mainly marked by the height dimension of the profile section (the thickness dimension of the door and window frame used in aluminum alloy doors and windows) and form a dimension series.

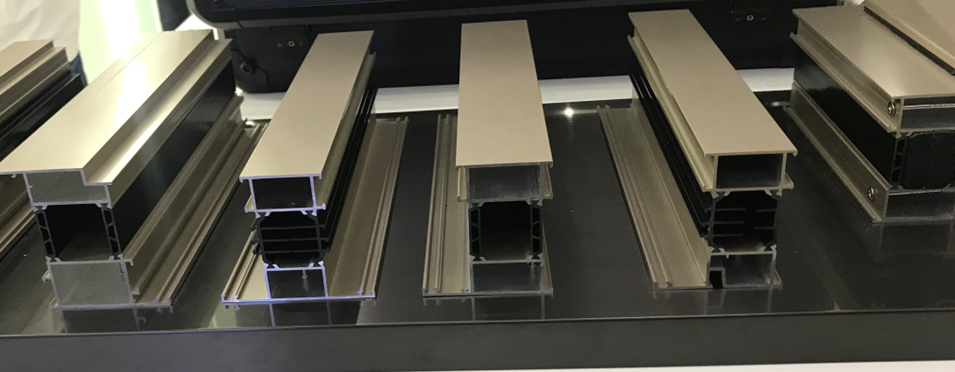

Xingda aluminum door and window profiles mainly include 40, 45, 50, 55, 60, 65, 70, 80, 90, 100mm and other size series. Among them, the size series for aluminum alloy windows is small, and the size series for aluminum alloy doors is too large.

Xingda Aluminum Profiles can provide aluminum profiles according to your drawings. Aluminum door and window profiles are divided into solid profiles and hollow profiles according to the cross-sectional shape, and the application of hollow profiles is relatively large. The wall thickness of aluminum door and window profiles is not less than 1.4mm for aluminum alloy windows, and not less than 2mm for aluminum alloy doors.

In which directions are aluminum profiles for doors and windows applied?

Xingda door and window aluminum profile is a material commonly used in the manufacture of door and window frames, which is made of aluminum alloy. It has been widely used in the field of construction and decoration. Aluminum profiles for doors and windows can be applied in the following directions:

Window and door frames: The most common use is to make frames for doors and windows. Door and window frames made of aluminum profiles can provide stable structural support while maintaining a small weight for easy installation and operation.

Sun room and greenhouse: Aluminum profiles can be used to build structures such as sun rooms and greenhouses. Its lightweight nature supports large expanses of glass, creating a light-filled environment.

Partitions and partition walls: Aluminum profiles can be used to make interior partitions and partition walls. These structures can divide the space according to the need, achieve privacy and functional division.

Aluminum profiles for doors and windows that Xingda can provide?

1. Aluminum profiles for casement windows: This profile is suitable for making traditional casement windows, with a straight and simple appearance. Common models are 60 series, 70 series and so on.

2. Sliding window aluminum profiles: used to make sliding windows, common models include 80 series, 90 series, etc. Sliding window profiles usually have a double-track or three-track design, so that the window can be opened by sliding.

3. Broken bridge aluminum profile: The broken bridge aluminum alloy profile is equipped with heat insulation strips between the indoor and outdoor surfaces, which improves the heat insulation performance of windows or doors and helps to save energy. Common models are 55 series, 65 series and so on.

4. Airtight sealing window aluminum profile: This profile is suitable for windows requiring high airtightness, which can effectively isolate the penetration of outside air, water and noise. Common models are 70 series, 80 series and so on.

5. Aluminum profiles for sliding doors: Suitable for making indoor or outdoor sliding doors, the common models are 80 series, 100 series, etc.

6. Aluminum profiles for folding doors: Used to make folding doors, suitable for spaces that require large openings. The common models are 100 series, 120 series, etc.

7. Sun room and greenhouse aluminum profiles: These profiles are used to build structures such as sun rooms and greenhouses. They usually need to be able to bear the weight of the glass plate. The common models are 130 series and 150 series.

8. Special profiles: For special design requirements, there are also various special-shaped aluminum profiles, such as arcs and triangles.

Processing flow of aluminum alloy door and window profiles:

Material cutting→2. Drilling→3. Assembly→4. Protection or packaging

1. Material cutting: It is the first process of making aluminum alloy doors and windows, and it is also a key process. Cutting equipment is mainly used for material cutting. The length of material should be determined according to the design requirements and with reference to the large-scale construction drawings of doors and windows. Accurate cutting is required; otherwise, it is difficult to guarantee the squareness of doors and windows, and the error value of the cutting material size should be controlled within 2mm.

Generally speaking, right-angle cutting should be used for sliding doors and windows; 45° angle cutting should be used for casement doors and windows; other types should be cut according to the assembly method.

2. Drilling: The frame and leaf assembly of aluminum alloy doors and windows is generally connected by screws, and holes need to be drilled at the corresponding positions. Profile drilling can be done with a small bench drill or a pistol drill.

The former can effectively ensure the accuracy of the drilling position because of the workbench; while the latter is because of the convenience of operation.

Before drilling, the wire should be positioned on the profile according to the assembly requirements. It is required that the drilling position is accurate and the hole diameter is suitable. Do not repeatedly change the drilling on the surface of the profile, because once the hole is formed, it is difficult to repair.

3. Assembling: The profiles are connected and assembled with screws through the connectors according to the requirements of the large-scale construction drawing. There are three ways to assemble aluminum alloy doors and windows: 45° angled joint, right angled joint and vertical joint.

The connection of horizontal and vertical rods generally adopts special connectors or aluminum angles, and then fixes them with screws, bolts or aluminum rivets.

All that’s left is to wrap it up and protect it.

What are the surface treatment methods of aluminum alloy doors and windows?

1. Anodizing

Overcoming the defects of aluminum alloy surface hardness, wear resistance, etc., anodized aluminum profiles, antistatic, easy to clean without dust collection, excellent heat dissipation, super strong metal texture in appearance, high-end and beautiful, uniform color, No fading, effectively improve the bonding force of organic coating and inorganic covering layer. Anodizing is currently the most widely used and most successful surface treatment technology for doors and windows.

2.electrophoresis

Electrophoresis means that the electrophoretic coating is on the cathode and anode. Under the action of voltage, the charged coating ions move to the cathode.

And it interacts with the alkalinity generated on the surface of the cathode to form insoluble matter, which is deposited on the surface of the profile.

3. Spray electrostatic powder.

Under the action of static electricity, the powder is evenly adsorbed on the surface of the workpiece to form a powder coating, and the powder is evenly adsorbed on the surface of the workpiece to form a powder coating; superior to coating processes.

Advantages and disadvantages of electrostatic powder coating.

4. fluorocarbon spraying.

The basic process of fluorocarbon spraying:

Pretreatment process: aluminum degreasing and decontamination → washing → alkali washing (degreasing) → washing → pickling → washing → chromium washing → pure washing.

Spraying process: Spray primer → topcoat → cover varnish → baking (180-250°C) → quality inspection.

Advantages and disadvantages of fluorocarbon spraying.

5. Frosted cloth treatment

The main function is surface cleaning. Sandblasting of aluminum alloy doors and windows before painting (painting or plastic spraying) can increase the surface roughness, which has a certain contribution to the improvement of adhesion, but the contribution is limited. It avoids the defect that bright aluminum alloy profiles will cause light interference in certain environments and conditions in building decoration. Its surface is as delicate and soft as brocade, which is very popular in the market, but the existing frosted materials must be overcome. Surface grit is uneven and lack of patterning can be seen.

6. wood grain transfer

As the name suggests, wood grain transfer printing is a surface treatment technology that reproduces various wood grain textures on the surface of aluminum profiles. Because wood grain color satisfies consumers’ pursuit of a natural and comfortable life, it contains a huge potential market. Xingda doors and windows are found to have clear surface patterns, pure colors, and strong sense of hierarchy (currently popular are skin lines, BMW lines, etc.), and are enthusiastically sought after by many consumers. The wood grain transfer printing has excellent anti-aging and fading, corrosion resistance and weather resistance, fully displaying the beautiful wood grain texture, and adding a lot of color to the home environment.

Do you offer window and door profile accessories?

Yes, if you need, Xingda can provide related accessories for door and window aluminum profiles, such as door locks, handles, stays, hinges, hinges, door closers, handles, latches, etc.

What is the minimum order quantity for door and window profiles?

Xingda accepts small batch orders, the minimum order quantity for door and window profiles is 300kg per model

Are there door and window aluminum profile molds suitable for your country’s market?

Yes, Xingda knows your country’s market very well, we have many molds for each country’s door and window series. Xingda has a lot of aluminum profile molds for doors and windows, and keeps developing new ones, so we can’t list all the molds in the catalogue, if you can tell us, what country design or what kind of profile are you looking for, that’s It will be of great help to both of us. We can provide product catalog according to your request.

How do we calculate the weight of aluminum profiles for doors and windows?

Xingda has drawing weight and actual weight for you to choose, you can choose one of the methods to calculate the weight of aluminum profiles for doors and windows

How to check the quality of door and window profile samples?

Xingda provides 10 cm long samples to customize the profile after starting the mold. You can choose to let us send you the door and window samples for inspection, or you can take pictures and videos of the door and window profiles for you to confirm

Xingda:your preferred door and window aluminum profile manufacturer

Xingda aluminum profiles for doors and windows can withstand high loads and can be processed according to your actual needs. It is not easy to deform in high temperature environments and has received positive feedback from customers.

As a popular choice for doors and windows of modern buildings, aluminum profiles for doors and windows bring you a fresh and simple visual effect.At the same time, it also provides you with a good experience.

Xingda uses imported nylon heat insulation strips, which have excellent anti-aging and anti-ultraviolet properties, and the thermal expansion coefficient is close to that of aluminum profiles.Ensure that the heat insulation strip is closely combined with the aluminum profile under the condition of large temperature difference

Aluminum profiles for doors and windows are also suitable for large-scale

glass curtain walls and bay window designs, creating a modern architectural

appearance

As a professional aluminum profile manufacturer, Xingda can provide you with

one-stop service from aluminum extrusion production to aluminum deep processing

As a professional aluminum profile manufacturer and exporter with 30 years of manufacturing and sales experience, Xingda Aluminum specializes in manufacturing high-quality door and window extrusion profiles, which are suitable for various architectural doors and windows, such as family houses, villas, office buildings, Commercial buildings, hotels, hospitals, schools and public buildings, etc.

Xingda has a wide range of products from aluminum ingot casting, mold making, extrusion, anodizing, coloring, electrophoretic coating, electrostatic powder coating,

Wood grain production line, strip heat insulation and other complete production lines

Xingda provides door and window aluminum processing services such as bending, uncoiling, welding, punching, and cutting

Xingda positions itself as a global aluminum profile solution provider based in China, which can meet your different types of needs,

Choose from a wide range of finishes and colours, contact us today for an aluminum catalog and quote

Xingda can give you 100% quality control and competitive price

Aluminum Profiles for Doors and Windows :FAQ and Answers

Aluminum profiles for doors and windows can be made into sections of various

shapes and sizes through extrusion, cutting, welding and other processing

techniques to meet the needs of different architectural styles and interior

decoration. From simple modern to retro classic, from straight line to curve,

aluminum profiles can be flexibly applied to various design concepts to achieve

unique spatial effects. It can meet the needs of different scenarios and create

more creative and functional spaces for architects and designers.

Process flow of aluminum profiles for doors and windows?

Common problems and preventive measures of aluminum profiles for doors and windows?

How much is a ton of aluminum profiles for doors and windows?

What is the wall thickness standard of aluminum profiles for doors and windows?

How to calculate the content of aluminum alloy doors and windows aluminum profiles?

What are the hardware accessories for aluminum profiles of doors and windows?

Precautions for choosing aluminum profiles for doors and windows?

Specifications and dimensions of aluminum profiles for doors and windows?

Aluminum alloy doors and windows aluminum profile content reference table?

Loss of door and window profiles?

What is the difference between 70 series and 80 series of aluminum alloy door and window profiles?

What is the service life of aluminum profiles for doors and windows?

How to see the profile diagram of broken bridge aluminum doors and windows?

Aluminum door and window profile hardness?

Classification of aluminum window frame profiles?

Classification of aluminum door frame profiles?

What are the door and window profile series?

What are the types of energy-saving aluminum door and window profiles?

What are the series of broken bridge heat insulation aluminum alloy profiles?

What is a thermal break bridge aluminum profile?

What are the production processes of aluminum profiles for doors and windows?

The production process of aluminum alloy door and window profiles includes three major processes: smelting, extrusion molding, and coloring, and the coloring process includes three options: anodic oxidation, air oxidation, and fluorocarbon painting.

Raw materials: according to the actual aluminum alloy profiles that need to be produced, calculate the amount of various aluminum alloy components added, and effectively match various raw materials;

Smelting: The selected raw materials are added to the melting furnace for melting according to the processing technology regulations, and the slag and gas in the melt are reasonably removed according to the degassing and slagging refining methods;

Forging: Under certain forging process standards, the smelted aluminum liquid can be turned into round casting rods of various specifications and models after water cooling according to the deep water well forging system software.

2. Extrusion process of aluminum alloy door and window profiles

Extrusion molding is carried out on an automatic production line consisting of ingot heating, extrusion, cooling, tension straightening, sawing and other processes.

The equipment on the production line includes induction heating furnace, extrusion machine, furnace table, discharge conveyor, profile lifting and transferring device, cooling bed, tension leveler, storage table, tractor, sawing machine, etc.

Induction heating furnace, the heating temperature of the ingot is generally controlled at 400 ° C ~ 520 ° C, if the temperature is too high or too low, it will directly affect the extrusion molding. The extrusion machine generally adopts a single-action hydraulic press, and its tonnage is between 1200 tons and 2500 tons.

The diameter of the extrusion cylinder of the extrusion machine varies with the tonnage of the extrusion machine. The larger the tonnage of the extrusion machine, the larger the diameter of the extrusion cylinder.

The diameter of the extrusion cylinder is generally in the range of 150mm~300mm. The working temperature of the extrusion tool is 360°C~460°C, and the extrusion speed is 20 m/min~80m/min. Extrusion tools mainly include dies. Extrusion dies are divided into flat dies, split dies, tongue dies and splitter combined dies according to their structural characteristics. The production of aluminum alloy door and window profiles mostly uses flat dies and split split dies.

The discharge table receives the profile extruded from the extruder and transfers the profile to the discharge table. Most of the discharge workbench is a horizontal strip transport model, and the movement speed of the horizontal strip is synchronized with the extrusion speed.

The cooling bed is mostly of walking beam type, and a considerable number of fans are installed below to ensure uniform cooling of the profiles, so that the temperature of the profiles is lower than 70°C before straightening.

The tension straightening machine is equipped with torsion jaws, which can stretch and straighten while torsion correction. After the tension leveler is the material storage table, which provides profiles to the sawing machine table, and the sawing machine cuts the profiles according to the fixed length.

3. Coloring treatment of aluminum alloy door and window profiles

The surface treatment of aluminum alloy door and window profiles is mostly anodized to make the surface of the profiles silvery white. Surface treatment can enhance the profile appearance and prolong the service life of aluminum door and window profiles.

Anodizing process flow: loading→degreasing→water washing→alkali etching→warm water washing→cold water washing→neutralizing light→water washing→anodizing→cold water washing→warm water washing→sealing→drying→unloading→finished product inspection→packaging The thickness of the oxide film after anodic oxidation of aluminum door and window profiles is not less than 10 μm.

The surface treatment of aluminum door and window profiles can also be colored. Aluminum profiles that require other colors can be obtained by natural oxidation coloring, electrolytic coloring and dipping coloring.

How to connect aluminum profiles for doors and windows?

Mechanical connection

Mechanical connection is a common connection method, which connects two or more materials together through fasteners such as screws and expansion bolts. It is a simple and reliable connection method. When connecting aluminum profiles for doors and windows, we can use corner codes, plate connectors and other materials, and connect them to the aluminum profiles with fasteners such as screws or expansion bolts.

Fusion connection

Welding connection is a high-strength connection method, which forms a whole by welding two or more materials together to achieve a tight and seamless connection effect. When connecting aluminum profiles for doors and windows, we can use arc welding, argon arc welding, etc. for welding to achieve a firm connection.

Adhesive connection

Adhesive bonding is a method of joining materials together using glue or adhesives. Unlike mechanical bonding and fusion bonding, the bonding effect depends on the performance and maintenance of the adhesive. When connecting the aluminum profiles of doors and windows, we can use special glue or adhesives to connect the aluminum profiles of doors and windows together.

No matter which connection method is used, we should pay attention to the following points when connecting aluminum profiles for doors and windows:

• Suitable materials and fasteners must be used to enable the connection to withstand the loads under normal service conditions.

• Before connecting, the surface of aluminum profiles for doors and windows must be carefully cleaned to ensure that the surface is clean and free of oil.

• When connecting, you must strictly follow the connection method to ensure that the connection is firm and reliable.

Generally speaking, there are various connection methods for aluminum profiles of doors and windows, and we can choose different connection methods according to specific conditions to achieve a good connection effect. At the same time, when connecting aluminum profiles for doors and windows, the connection method must be strictly followed to ensure that the connection is firm and reliable.

Why is aluminum most suitable for door and window profiles?

Aluminum is a metal with light weight, good toughness and corrosion resistance, so it is widely used in the manufacture of door and window profiles. Here are a few important reasons why aluminum profiles are best suited for windows and doors:

Lightweight and corrosion-resistant: Aluminum material has low density and light weight, which makes the installation of aluminum doors and windows more convenient. Aluminum has excellent anti-oxidation and corrosion resistance. Even if it is used for a long time in a humid environment, it will not rust and can maintain a long-term aesthetics.

High strength and good rigidity: aluminum profile products have high strength, good rigidity, strong resistance to external impact, and are not easy to deform. In the manufacture of doors and windows, it is necessary to maintain a certain degree of rigidity, which is very important to ensure the service life and stability.

Good processability and diverse designs: aluminum profiles are easy to process, and can be flexibly processed and designed according to different door and window design requirements. In addition, the surface treatment of aluminum profiles can also achieve different colors and textures, so it has a wider degree of freedom in aesthetics and design.

Environmental protection and energy saving: aluminum products can be recycled and reused, which meets a large number of environmental protection requirements. Moreover, doors and windows made of aluminum profiles have good sound insulation and thermal insulation properties, which can effectively reduce energy consumption and environmental protection emissions.

Therefore, aluminum profiles are currently one of the best materials in the manufacture of doors and windows. Aluminum products not only ensure the safety, stability and durability of doors and windows, but also meet different design requirements. At the same time, they also have the advantages of environmental protection and energy saving, so they have irreplaceable advantages in the door and window industry.

What are the mechanical properties of aluminum profile doors and windows?

High strength. Aluminum is a metal material with high strength, and its hardness and compression resistance are relatively strong. During the manufacturing process of doors and windows, the fastness and bearing capacity of aluminum ensure the overall stability and safety of doors and windows.

Strong corrosion resistance. Aluminum has excellent corrosion resistance and can be used for a long time in various harsh environments without damage. This means that aluminum profile doors and windows will not corrode, rust, or deform, ensuring the long-term use of doors and windows.

Good thermal conductivity. Aluminum has good thermal conductivity, which can quickly transfer heat, reduce local heat accumulation in doors and windows, ensure indoor ventilation and uniform temperature distribution, and improve the comfort of doors and windows.

Lightweight. Aluminum is a lighter metal material that is easy to handle and install. Lightweight doors and windows play a very positive role in reducing the load of the overall building structure.

What is the price of aluminum profiles for doors and windows?

The price of aluminum profiles for doors and windows varies greatly. The main factors are as follows:

Aluminum profile cost: The raw material of aluminum profiles for doors and windows is aluminum ingots. If the price of aluminum ingots decreases, the price of aluminum profiles for doors and windows will also decrease.

Shape and size: The more complex the shape and size of aluminum profiles for doors and windows, the higher the price.

To meet higher requirements for door and window design. Therefore, the price of aluminum profiles for doors and windows will be affected by the shape and size.

Processing methods: There are many processing methods for aluminum profiles, such as anodizing, powder coating, coating process, etc. for surface treatment. Different processing methods have different degrees of complexity, which means that prices are also different.

Purchase quantity: If you need more aluminum profiles, the price will be cheaper, because the batch price is different.

Wall thickness: The wall thickness is different, which means that the meter weight is different, so the price is also different.

What are the specifications of doors and windows?

The specifications and dimensions of aluminum door and window profiles are mainly marked by the height dimension of the profile section (the thickness dimension of the door and window frame used in aluminum alloy doors and windows) and form a dimension series.

Xingda aluminum door and window profiles mainly include 40, 45, 50, 55, 60, 65, 70, 80, 90, 100mm and other size series. Among them, the size series for aluminum alloy windows is small, and the size series for aluminum alloy doors is too large.

Xingda Aluminum Profiles can provide aluminum profiles according to your drawings. Aluminum door and window profiles are divided into solid profiles and hollow profiles according to the cross-sectional shape, and the application of hollow profiles is relatively large. The wall thickness of aluminum door and window profiles is not less than 1.4mm for aluminum alloy windows, and not less than 2mm for aluminum alloy doors.

In which directions are aluminum profiles for doors and windows applied?

Xingda door and window aluminum profile is a material commonly used in the manufacture of door and window frames, which is made of aluminum alloy. It has been widely used in the field of construction and decoration. Aluminum profiles for doors and windows can be applied in the following directions:

Window and door frames: The most common use is to make frames for doors and windows. Door and window frames made of aluminum profiles can provide stable structural support while maintaining a small weight for easy installation and operation.

Sun room and greenhouse: Aluminum profiles can be used to build structures such as sun rooms and greenhouses. Its lightweight nature supports large expanses of glass, creating a light-filled environment.

Partitions and partition walls: Aluminum profiles can be used to make interior partitions and partition walls. These structures can divide the space according to the need, achieve privacy and functional division.

Aluminum profiles for doors and windows that Xingda can provide?

1. Aluminum profiles for casement windows: This profile is suitable for making traditional casement windows, with a straight and simple appearance. Common models are 60 series, 70 series and so on.

2. Sliding window aluminum profiles: used to make sliding windows, common models include 80 series, 90 series, etc. Sliding window profiles usually have a double-track or three-track design, so that the window can be opened by sliding.

3. Broken bridge aluminum profile: The broken bridge aluminum alloy profile is equipped with heat insulation strips between the indoor and outdoor surfaces, which improves the heat insulation performance of windows or doors and helps to save energy. Common models are 55 series, 65 series and so on.

4. Airtight sealing window aluminum profile: This profile is suitable for windows requiring high airtightness, which can effectively isolate the penetration of outside air, water and noise. Common models are 70 series, 80 series and so on.

5. Aluminum profiles for sliding doors: Suitable for making indoor or outdoor sliding doors, the common models are 80 series, 100 series, etc.

6. Aluminum profiles for folding doors: Used to make folding doors, suitable for spaces that require large openings. The common models are 100 series, 120 series, etc.

7. Sun room and greenhouse aluminum profiles: These profiles are used to build structures such as sun rooms and greenhouses. They usually need to be able to bear the weight of the glass plate. The common models are 130 series and 150 series.

8. Special profiles: For special design requirements, there are also various special-shaped aluminum profiles, such as arcs and triangles.

Processing flow of aluminum alloy door and window profiles:

Material cutting→2. Drilling→3. Assembly→4. Protection or packaging

1. Material cutting: It is the first process of making aluminum alloy doors and windows, and it is also a key process. Cutting equipment is mainly used for material cutting. The length of material should be determined according to the design requirements and with reference to the large-scale construction drawings of doors and windows. Accurate cutting is required; otherwise, it is difficult to guarantee the squareness of doors and windows, and the error value of the cutting material size should be controlled within 2mm.

Generally speaking, right-angle cutting should be used for sliding doors and windows; 45° angle cutting should be used for casement doors and windows; other types should be cut according to the assembly method.

2. Drilling: The frame and leaf assembly of aluminum alloy doors and windows is generally connected by screws, and holes need to be drilled at the corresponding positions. Profile drilling can be done with a small bench drill or a pistol drill.

The former can effectively ensure the accuracy of the drilling position because of the workbench; while the latter is because of the convenience of operation.

Before drilling, the wire should be positioned on the profile according to the assembly requirements. It is required that the drilling position is accurate and the hole diameter is suitable. Do not repeatedly change the drilling on the surface of the profile, because once the hole is formed, it is difficult to repair.

3. Assembling: The profiles are connected and assembled with screws through the connectors according to the requirements of the large-scale construction drawing. There are three ways to assemble aluminum alloy doors and windows: 45° angled joint, right angled joint and vertical joint.

The connection of horizontal and vertical rods generally adopts special connectors or aluminum angles, and then fixes them with screws, bolts or aluminum rivets.

All that’s left is to wrap it up and protect it.

What are the surface treatment methods of aluminum alloy doors and windows?

1. Anodizing

Overcoming the defects of aluminum alloy surface hardness, wear resistance, etc., anodized aluminum profiles, antistatic, easy to clean without dust collection, excellent heat dissipation, super strong metal texture in appearance, high-end and beautiful, uniform color, No fading, effectively improve the bonding force of organic coating and inorganic covering layer. Anodizing is currently the most widely used and most successful surface treatment technology for doors and windows.

2.electrophoresis

Electrophoresis means that the electrophoretic coating is on the cathode and anode. Under the action of voltage, the charged coating ions move to the cathode.

And it interacts with the alkalinity generated on the surface of the cathode to form insoluble matter, which is deposited on the surface of the profile.

3. Spray electrostatic powder.

Under the action of static electricity, the powder is evenly adsorbed on the surface of the workpiece to form a powder coating, and the powder is evenly adsorbed on the surface of the workpiece to form a powder coating; superior to coating processes.

Advantages and disadvantages of electrostatic powder coating.

4. fluorocarbon spraying.

The basic process of fluorocarbon spraying:

Pretreatment process: aluminum degreasing and decontamination → washing → alkali washing (degreasing) → washing → pickling → washing → chromium washing → pure washing.

Spraying process: Spray primer → topcoat → cover varnish → baking (180-250°C) → quality inspection.

Advantages and disadvantages of fluorocarbon spraying.

5. Frosted cloth treatment

The main function is surface cleaning. Sandblasting of aluminum alloy doors and windows before painting (painting or plastic spraying) can increase the surface roughness, which has a certain contribution to the improvement of adhesion, but the contribution is limited. It avoids the defect that bright aluminum alloy profiles will cause light interference in certain environments and conditions in building decoration. Its surface is as delicate and soft as brocade, which is very popular in the market, but the existing frosted materials must be overcome. Surface grit is uneven and lack of patterning can be seen.

6. wood grain transfer

As the name suggests, wood grain transfer printing is a surface treatment technology that reproduces various wood grain textures on the surface of aluminum profiles. Because wood grain color satisfies consumers’ pursuit of a natural and comfortable life, it contains a huge potential market. Xingda doors and windows are found to have clear surface patterns, pure colors, and strong sense of hierarchy (currently popular are skin lines, BMW lines, etc.), and are enthusiastically sought after by many consumers. The wood grain transfer printing has excellent anti-aging and fading, corrosion resistance and weather resistance, fully displaying the beautiful wood grain texture, and adding a lot of color to the home environment.

Do you offer window and door profile accessories?

Yes, if you need, Xingda can provide related accessories for door and window aluminum profiles, such as door locks, handles, stays, hinges, hinges, door closers, handles, latches, etc.

What is the minimum order quantity for door and window profiles?

Xingda accepts small batch orders, the minimum order quantity for door and window profiles is 300kg per model

Are there door and window aluminum profile molds suitable for your country’s market?

Yes, Xingda knows your country’s market very well, we have many molds for each country’s door and window series. Xingda has a lot of aluminum profile molds for doors and windows, and keeps developing new ones, so we can’t list all the molds in the catalogue, if you can tell us, what country design or what kind of profile are you looking for, that’s It will be of great help to both of us. We can provide product catalog according to your request.

How do we calculate the weight of aluminum profiles for doors and windows?

Xingda has drawing weight and actual weight for you to choose, you can choose one of the methods to calculate the weight of aluminum profiles for doors and windows

How to check the quality of door and window profile samples?

Xingda provides 10 cm long samples to customize the profile after starting the mold. You can choose to let us send you the door and window samples for inspection, or you can take pictures and videos of the door and window profiles for you to confirm

Xingda:your preferred door and window aluminum profile manufacturer

Xingda aluminum profiles for doors and windows can withstand high loads and can be processed according to your actual needs. It is not easy to deform in high temperature environments and has received positive feedback from customers.

As a popular choice for doors and windows of modern buildings, aluminum profiles for doors and windows bring you a fresh and simple visual effect.At the same time, it also provides you with a good experience.

Xingda uses imported nylon heat insulation strips, which have excellent anti-aging and anti-ultraviolet properties, and the thermal expansion coefficient is close to that of aluminum profiles.Ensure that the heat insulation strip is closely combined with the aluminum profile under the condition of large temperature difference

Aluminum profiles for doors and windows are also suitable for large-scale

glass curtain walls and bay window designs, creating a modern architectural

appearance

As a professional aluminum profile manufacturer, Xingda can provide you with

one-stop service from aluminum extrusion production to aluminum deep processing

As a professional aluminum profile manufacturer and exporter with 30 years of manufacturing and sales experience, Xingda Aluminum specializes in manufacturing high-quality door and window extrusion profiles, which are suitable for various architectural doors and windows, such as family houses, villas, office buildings, Commercial buildings, hotels, hospitals, schools and public buildings, etc.

Xingda has a wide range of products from aluminum ingot casting, mold making, extrusion, anodizing, coloring, electrophoretic coating, electrostatic powder coating,

Wood grain production line, strip heat insulation and other complete production lines

Xingda provides door and window aluminum processing services such as bending, uncoiling, welding, punching, and cutting

Xingda positions itself as a global aluminum profile solution provider based in China, which can meet your different types of needs,

Choose from a wide range of finishes and colours, contact us today for an aluminum catalog and quote

Xingda can give you 100% quality control and competitive price

Aluminum Profiles for Doors and Windows :FAQ and Answers

Aluminum profiles for doors and windows can be made into sections of various

shapes and sizes through extrusion, cutting, welding and other processing

techniques to meet the needs of different architectural styles and interior

decoration. From simple modern to retro classic, from straight line to curve,

aluminum profiles can be flexibly applied to various design concepts to achieve

unique spatial effects. It can meet the needs of different scenarios and create

more creative and functional spaces for architects and designers.

Process flow of aluminum profiles for doors and windows?

Common problems and preventive measures of aluminum profiles for doors and windows?

How much is a ton of aluminum profiles for doors and windows?

What is the wall thickness standard of aluminum profiles for doors and windows?

How to calculate the content of aluminum alloy doors and windows aluminum profiles?

What are the hardware accessories for aluminum profiles of doors and windows?

Precautions for choosing aluminum profiles for doors and windows?

Specifications and dimensions of aluminum profiles for doors and windows?

Aluminum alloy doors and windows aluminum profile content reference table?

Loss of door and window profiles?

What is the difference between 70 series and 80 series of aluminum alloy door and window profiles?

What is the service life of aluminum profiles for doors and windows?

How to see the profile diagram of broken bridge aluminum doors and windows?

Aluminum door and window profile hardness?

Classification of aluminum window frame profiles?

Classification of aluminum door frame profiles?

What are the door and window profile series?

What are the types of energy-saving aluminum door and window profiles?

What are the series of broken bridge heat insulation aluminum alloy profiles?

What is a thermal break bridge aluminum profile?

What are the production processes of aluminum profiles for doors and windows?

The production process of aluminum alloy door and window profiles includes three major processes: smelting, extrusion molding, and coloring, and the coloring process includes three options: anodic oxidation, air oxidation, and fluorocarbon painting.

Raw materials: according to the actual aluminum alloy profiles that need to be produced, calculate the amount of various aluminum alloy components added, and effectively match various raw materials;

Smelting: The selected raw materials are added to the melting furnace for melting according to the processing technology regulations, and the slag and gas in the melt are reasonably removed according to the degassing and slagging refining methods;

Forging: Under certain forging process standards, the smelted aluminum liquid can be turned into round casting rods of various specifications and models after water cooling according to the deep water well forging system software.

2. Extrusion process of aluminum alloy door and window profiles

Extrusion molding is carried out on an automatic production line consisting of ingot heating, extrusion, cooling, tension straightening, sawing and other processes.

The equipment on the production line includes induction heating furnace, extrusion machine, furnace table, discharge conveyor, profile lifting and transferring device, cooling bed, tension leveler, storage table, tractor, sawing machine, etc.

Induction heating furnace, the heating temperature of the ingot is generally controlled at 400 ° C ~ 520 ° C, if the temperature is too high or too low, it will directly affect the extrusion molding. The extrusion machine generally adopts a single-action hydraulic press, and its tonnage is between 1200 tons and 2500 tons.

The diameter of the extrusion cylinder of the extrusion machine varies with the tonnage of the extrusion machine. The larger the tonnage of the extrusion machine, the larger the diameter of the extrusion cylinder.

The diameter of the extrusion cylinder is generally in the range of 150mm~300mm. The working temperature of the extrusion tool is 360°C~460°C, and the extrusion speed is 20 m/min~80m/min. Extrusion tools mainly include dies. Extrusion dies are divided into flat dies, split dies, tongue dies and splitter combined dies according to their structural characteristics. The production of aluminum alloy door and window profiles mostly uses flat dies and split split dies.

The discharge table receives the profile extruded from the extruder and transfers the profile to the discharge table. Most of the discharge workbench is a horizontal strip transport model, and the movement speed of the horizontal strip is synchronized with the extrusion speed.

The cooling bed is mostly of walking beam type, and a considerable number of fans are installed below to ensure uniform cooling of the profiles, so that the temperature of the profiles is lower than 70°C before straightening.

The tension straightening machine is equipped with torsion jaws, which can stretch and straighten while torsion correction. After the tension leveler is the material storage table, which provides profiles to the sawing machine table, and the sawing machine cuts the profiles according to the fixed length.

3. Coloring treatment of aluminum alloy door and window profiles

The surface treatment of aluminum alloy door and window profiles is mostly anodized to make the surface of the profiles silvery white. Surface treatment can enhance the profile appearance and prolong the service life of aluminum door and window profiles.

Anodizing process flow: loading→degreasing→water washing→alkali etching→warm water washing→cold water washing→neutralizing light→water washing→anodizing→cold water washing→warm water washing→sealing→drying→unloading→finished product inspection→packaging The thickness of the oxide film after anodic oxidation of aluminum door and window profiles is not less than 10 μm.

The surface treatment of aluminum door and window profiles can also be colored. Aluminum profiles that require other colors can be obtained by natural oxidation coloring, electrolytic coloring and dipping coloring.

How to connect aluminum profiles for doors and windows?

Mechanical connection

Mechanical connection is a common connection method, which connects two or more materials together through fasteners such as screws and expansion bolts. It is a simple and reliable connection method. When connecting aluminum profiles for doors and windows, we can use corner codes, plate connectors and other materials, and connect them to the aluminum profiles with fasteners such as screws or expansion bolts.

Fusion connection

Welding connection is a high-strength connection method, which forms a whole by welding two or more materials together to achieve a tight and seamless connection effect. When connecting aluminum profiles for doors and windows, we can use arc welding, argon arc welding, etc. for welding to achieve a firm connection.

Adhesive connection

Adhesive bonding is a method of joining materials together using glue or adhesives. Unlike mechanical bonding and fusion bonding, the bonding effect depends on the performance and maintenance of the adhesive. When connecting the aluminum profiles of doors and windows, we can use special glue or adhesives to connect the aluminum profiles of doors and windows together.

No matter which connection method is used, we should pay attention to the following points when connecting aluminum profiles for doors and windows:

• Suitable materials and fasteners must be used to enable the connection to withstand the loads under normal service conditions.

• Before connecting, the surface of aluminum profiles for doors and windows must be carefully cleaned to ensure that the surface is clean and free of oil.

• When connecting, you must strictly follow the connection method to ensure that the connection is firm and reliable.

Generally speaking, there are various connection methods for aluminum profiles of doors and windows, and we can choose different connection methods according to specific conditions to achieve a good connection effect. At the same time, when connecting aluminum profiles for doors and windows, the connection method must be strictly followed to ensure that the connection is firm and reliable.

Why is aluminum most suitable for door and window profiles?

Aluminum is a metal with light weight, good toughness and corrosion resistance, so it is widely used in the manufacture of door and window profiles. Here are a few important reasons why aluminum profiles are best suited for windows and doors:

Lightweight and corrosion-resistant: Aluminum material has low density and light weight, which makes the installation of aluminum doors and windows more convenient. Aluminum has excellent anti-oxidation and corrosion resistance. Even if it is used for a long time in a humid environment, it will not rust and can maintain a long-term aesthetics.

High strength and good rigidity: aluminum profile products have high strength, good rigidity, strong resistance to external impact, and are not easy to deform. In the manufacture of doors and windows, it is necessary to maintain a certain degree of rigidity, which is very important to ensure the service life and stability.

Good processability and diverse designs: aluminum profiles are easy to process, and can be flexibly processed and designed according to different door and window design requirements. In addition, the surface treatment of aluminum profiles can also achieve different colors and textures, so it has a wider degree of freedom in aesthetics and design.

Environmental protection and energy saving: aluminum products can be recycled and reused, which meets a large number of environmental protection requirements. Moreover, doors and windows made of aluminum profiles have good sound insulation and thermal insulation properties, which can effectively reduce energy consumption and environmental protection emissions.

Therefore, aluminum profiles are currently one of the best materials in the manufacture of doors and windows. Aluminum products not only ensure the safety, stability and durability of doors and windows, but also meet different design requirements. At the same time, they also have the advantages of environmental protection and energy saving, so they have irreplaceable advantages in the door and window industry.

What are the mechanical properties of aluminum profile doors and windows?

High strength. Aluminum is a metal material with high strength, and its hardness and compression resistance are relatively strong. During the manufacturing process of doors and windows, the fastness and bearing capacity of aluminum ensure the overall stability and safety of doors and windows.

Strong corrosion resistance. Aluminum has excellent corrosion resistance and can be used for a long time in various harsh environments without damage. This means that aluminum profile doors and windows will not corrode, rust, or deform, ensuring the long-term use of doors and windows.

Good thermal conductivity. Aluminum has good thermal conductivity, which can quickly transfer heat, reduce local heat accumulation in doors and windows, ensure indoor ventilation and uniform temperature distribution, and improve the comfort of doors and windows.

Lightweight. Aluminum is a lighter metal material that is easy to handle and install. Lightweight doors and windows play a very positive role in reducing the load of the overall building structure.

What is the price of aluminum profiles for doors and windows?

The price of aluminum profiles for doors and windows varies greatly. The main factors are as follows:

Aluminum profile cost: The raw material of aluminum profiles for doors and windows is aluminum ingots. If the price of aluminum ingots decreases, the price of aluminum profiles for doors and windows will also decrease.

Shape and size: The more complex the shape and size of aluminum profiles for doors and windows, the higher the price.

To meet higher requirements for door and window design. Therefore, the price of aluminum profiles for doors and windows will be affected by the shape and size.

Processing methods: There are many processing methods for aluminum profiles, such as anodizing, powder coating, coating process, etc. for surface treatment. Different processing methods have different degrees of complexity, which means that prices are also different.

Purchase quantity: If you need more aluminum profiles, the price will be cheaper, because the batch price is different.

Wall thickness: The wall thickness is different, which means that the meter weight is different, so the price is also different.

What are the specifications of doors and windows?

The specifications and dimensions of aluminum door and window profiles are mainly marked by the height dimension of the profile section (the thickness dimension of the door and window frame used in aluminum alloy doors and windows) and form a dimension series.

Xingda aluminum door and window profiles mainly include 40, 45, 50, 55, 60, 65, 70, 80, 90, 100mm and other size series. Among them, the size series for aluminum alloy windows is small, and the size series for aluminum alloy doors is too large.

Xingda Aluminum Profiles can provide aluminum profiles according to your drawings. Aluminum door and window profiles are divided into solid profiles and hollow profiles according to the cross-sectional shape, and the application of hollow profiles is relatively large. The wall thickness of aluminum door and window profiles is not less than 1.4mm for aluminum alloy windows, and not less than 2mm for aluminum alloy doors.

In which directions are aluminum profiles for doors and windows applied?

Xingda door and window aluminum profile is a material commonly used in the manufacture of door and window frames, which is made of aluminum alloy. It has been widely used in the field of construction and decoration. Aluminum profiles for doors and windows can be applied in the following directions:

Window and door frames: The most common use is to make frames for doors and windows. Door and window frames made of aluminum profiles can provide stable structural support while maintaining a small weight for easy installation and operation.

Sun room and greenhouse: Aluminum profiles can be used to build structures such as sun rooms and greenhouses. Its lightweight nature supports large expanses of glass, creating a light-filled environment.

Partitions and partition walls: Aluminum profiles can be used to make interior partitions and partition walls. These structures can divide the space according to the need, achieve privacy and functional division.

Aluminum profiles for doors and windows that Xingda can provide?

1. Aluminum profiles for casement windows: This profile is suitable for making traditional casement windows, with a straight and simple appearance. Common models are 60 series, 70 series and so on.

2. Sliding window aluminum profiles: used to make sliding windows, common models include 80 series, 90 series, etc. Sliding window profiles usually have a double-track or three-track design, so that the window can be opened by sliding.

3. Broken bridge aluminum profile: The broken bridge aluminum alloy profile is equipped with heat insulation strips between the indoor and outdoor surfaces, which improves the heat insulation performance of windows or doors and helps to save energy. Common models are 55 series, 65 series and so on.

4. Airtight sealing window aluminum profile: This profile is suitable for windows requiring high airtightness, which can effectively isolate the penetration of outside air, water and noise. Common models are 70 series, 80 series and so on.

5. Aluminum profiles for sliding doors: Suitable for making indoor or outdoor sliding doors, the common models are 80 series, 100 series, etc.

6. Aluminum profiles for folding doors: Used to make folding doors, suitable for spaces that require large openings. The common models are 100 series, 120 series, etc.

7. Sun room and greenhouse aluminum profiles: These profiles are used to build structures such as sun rooms and greenhouses. They usually need to be able to bear the weight of the glass plate. The common models are 130 series and 150 series.

8. Special profiles: For special design requirements, there are also various special-shaped aluminum profiles, such as arcs and triangles.

Processing flow of aluminum alloy door and window profiles:

Material cutting→2. Drilling→3. Assembly→4. Protection or packaging

1. Material cutting: It is the first process of making aluminum alloy doors and windows, and it is also a key process. Cutting equipment is mainly used for material cutting. The length of material should be determined according to the design requirements and with reference to the large-scale construction drawings of doors and windows. Accurate cutting is required; otherwise, it is difficult to guarantee the squareness of doors and windows, and the error value of the cutting material size should be controlled within 2mm.

Generally speaking, right-angle cutting should be used for sliding doors and windows; 45° angle cutting should be used for casement doors and windows; other types should be cut according to the assembly method.

2. Drilling: The frame and leaf assembly of aluminum alloy doors and windows is generally connected by screws, and holes need to be drilled at the corresponding positions. Profile drilling can be done with a small bench drill or a pistol drill.

The former can effectively ensure the accuracy of the drilling position because of the workbench; while the latter is because of the convenience of operation.

Before drilling, the wire should be positioned on the profile according to the assembly requirements. It is required that the drilling position is accurate and the hole diameter is suitable. Do not repeatedly change the drilling on the surface of the profile, because once the hole is formed, it is difficult to repair.

3. Assembling: The profiles are connected and assembled with screws through the connectors according to the requirements of the large-scale construction drawing. There are three ways to assemble aluminum alloy doors and windows: 45° angled joint, right angled joint and vertical joint.

The connection of horizontal and vertical rods generally adopts special connectors or aluminum angles, and then fixes them with screws, bolts or aluminum rivets.

All that’s left is to wrap it up and protect it.

What are the surface treatment methods of aluminum alloy doors and windows?

1. Anodizing

Overcoming the defects of aluminum alloy surface hardness, wear resistance, etc., anodized aluminum profiles, antistatic, easy to clean without dust collection, excellent heat dissipation, super strong metal texture in appearance, high-end and beautiful, uniform color, No fading, effectively improve the bonding force of organic coating and inorganic covering layer. Anodizing is currently the most widely used and most successful surface treatment technology for doors and windows.

2.electrophoresis

Electrophoresis means that the electrophoretic coating is on the cathode and anode. Under the action of voltage, the charged coating ions move to the cathode.

And it interacts with the alkalinity generated on the surface of the cathode to form insoluble matter, which is deposited on the surface of the profile.

3. Spray electrostatic powder.

Under the action of static electricity, the powder is evenly adsorbed on the surface of the workpiece to form a powder coating, and the powder is evenly adsorbed on the surface of the workpiece to form a powder coating; superior to coating processes.

Advantages and disadvantages of electrostatic powder coating.

4. fluorocarbon spraying.

The basic process of fluorocarbon spraying:

Pretreatment process: aluminum degreasing and decontamination → washing → alkali washing (degreasing) → washing → pickling → washing → chromium washing → pure washing.

Spraying process: Spray primer → topcoat → cover varnish → baking (180-250°C) → quality inspection.

Advantages and disadvantages of fluorocarbon spraying.

5. Frosted cloth treatment

The main function is surface cleaning. Sandblasting of aluminum alloy doors and windows before painting (painting or plastic spraying) can increase the surface roughness, which has a certain contribution to the improvement of adhesion, but the contribution is limited. It avoids the defect that bright aluminum alloy profiles will cause light interference in certain environments and conditions in building decoration. Its surface is as delicate and soft as brocade, which is very popular in the market, but the existing frosted materials must be overcome. Surface grit is uneven and lack of patterning can be seen.

6. wood grain transfer

As the name suggests, wood grain transfer printing is a surface treatment technology that reproduces various wood grain textures on the surface of aluminum profiles. Because wood grain color satisfies consumers’ pursuit of a natural and comfortable life, it contains a huge potential market. Xingda doors and windows are found to have clear surface patterns, pure colors, and strong sense of hierarchy (currently popular are skin lines, BMW lines, etc.), and are enthusiastically sought after by many consumers. The wood grain transfer printing has excellent anti-aging and fading, corrosion resistance and weather resistance, fully displaying the beautiful wood grain texture, and adding a lot of color to the home environment.

Do you offer window and door profile accessories?

Yes, if you need, Xingda can provide related accessories for door and window aluminum profiles, such as door locks, handles, stays, hinges, hinges, door closers, handles, latches, etc.

What is the minimum order quantity for door and window profiles?

Xingda accepts small batch orders, the minimum order quantity for door and window profiles is 300kg per model

Are there door and window aluminum profile molds suitable for your country’s market?

Yes, Xingda knows your country’s market very well, we have many molds for each country’s door and window series. Xingda has a lot of aluminum profile molds for doors and windows, and keeps developing new ones, so we can’t list all the molds in the catalogue, if you can tell us, what country design or what kind of profile are you looking for, that’s It will be of great help to both of us. We can provide product catalog according to your request.

How do we calculate the weight of aluminum profiles for doors and windows?

Xingda has drawing weight and actual weight for you to choose, you can choose one of the methods to calculate the weight of aluminum profiles for doors and windows

How to check the quality of door and window profile samples?

Xingda provides 10 cm long samples to customize the profile after starting the mold. You can choose to let us send you the door and window samples for inspection, or you can take pictures and videos of the door and window profiles for you to confirm